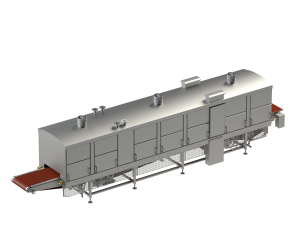

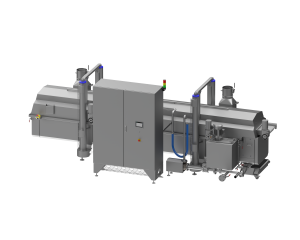

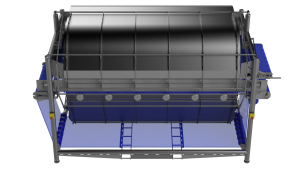

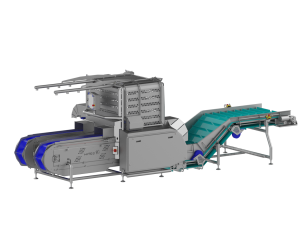

| The HiTec Pepper Decoring System is the perfect machine for decoring and segmenting peppers and is the newest generation of bell pepper decorer which has been specially developed to meet the high demands in the modern food processing industry. The bell peppers are placed by hand on the pocket lane, which then transports to the core / quart section. At each step, 4 recording units can always be filled simultaneously. Thanks to special pockets, the peppers remain perfectly oriented during the cutting and de-coring of the product.

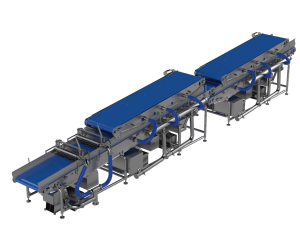

The product is moved step by step (standstill, displacement, standstill, etc.), making it very easy and controllable to place the product to be cut.The cut products are transported further through the pockets and unloaded at a turning point in a collection bin or directly onto a conveyor belt, so that the product stays together. The cutting waste / cores are transported directly to a waste volume or bin via an underlying conveyor belt.

The machine is designed according to the European safety standards. The machine is equipped with interlocked safety. The machine is entirely constructed of stainles s steel (304) and food grade products. Technical specification (PDS):

Product specifications peppers: o Min diameter 70mm o Max diameter 115mm o Height 120mm o Stalks If the stalks are longer than 50 mm then they need to be broken off by hand

|

With over 35 years of experience in the Food Industry, we advise, develop and produce high-quality tailor-made stainless steel solutions. We combine specific expertise and skills and focus on high quality, service, hygiene and safety in our work.

— Hitec BV