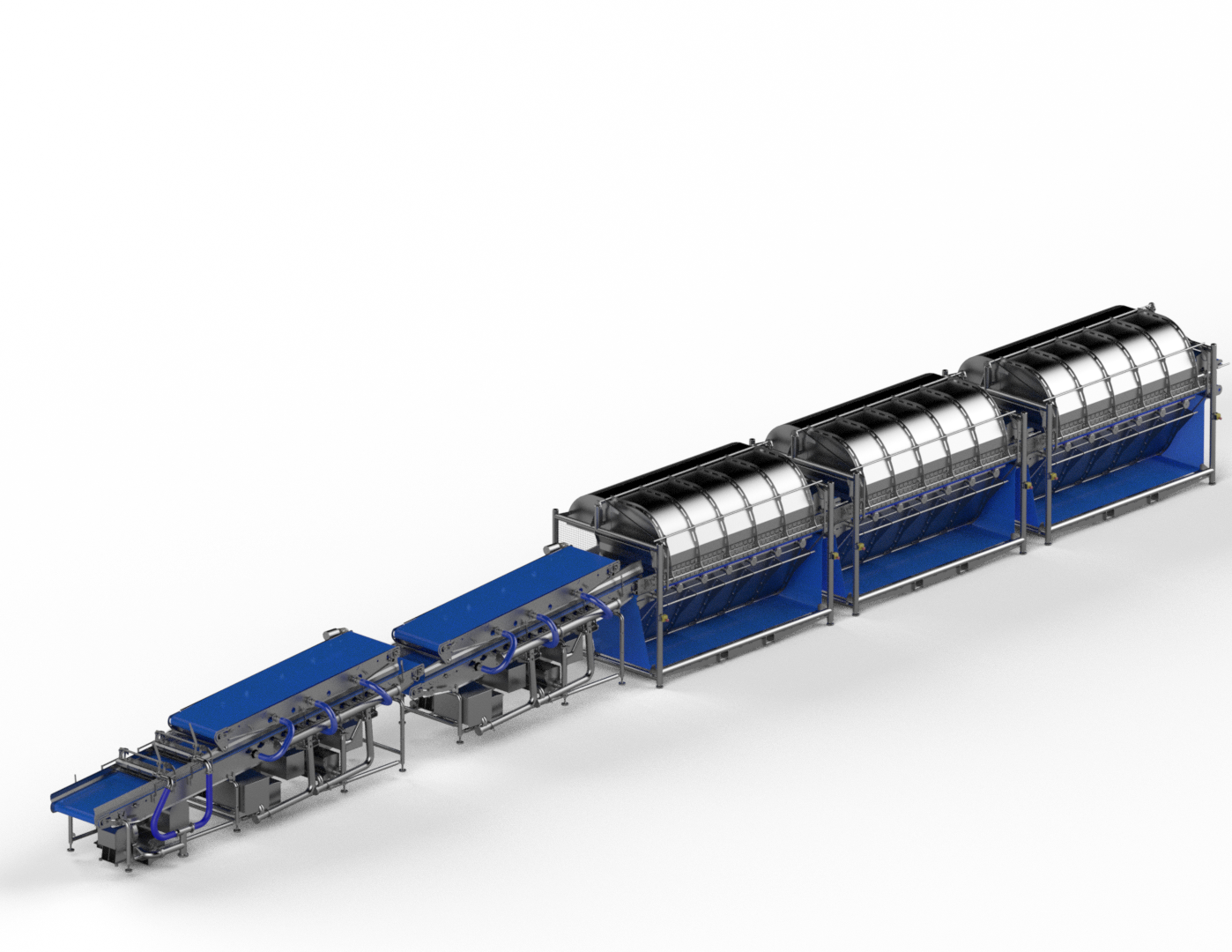

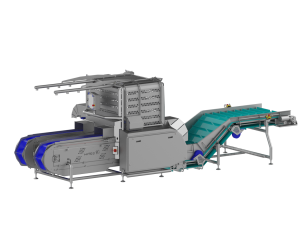

The HiTec Fresh Dryer is a modular system wich dries and cools the product to the desired moisture percentage and temperature as a follow up to the FDS & BDS process. It was developed specifically for drying delicate leafy vegetables and for creating a low attached moisture percentage with leafy vegetables moist percentages till 1%AW can be achieved.

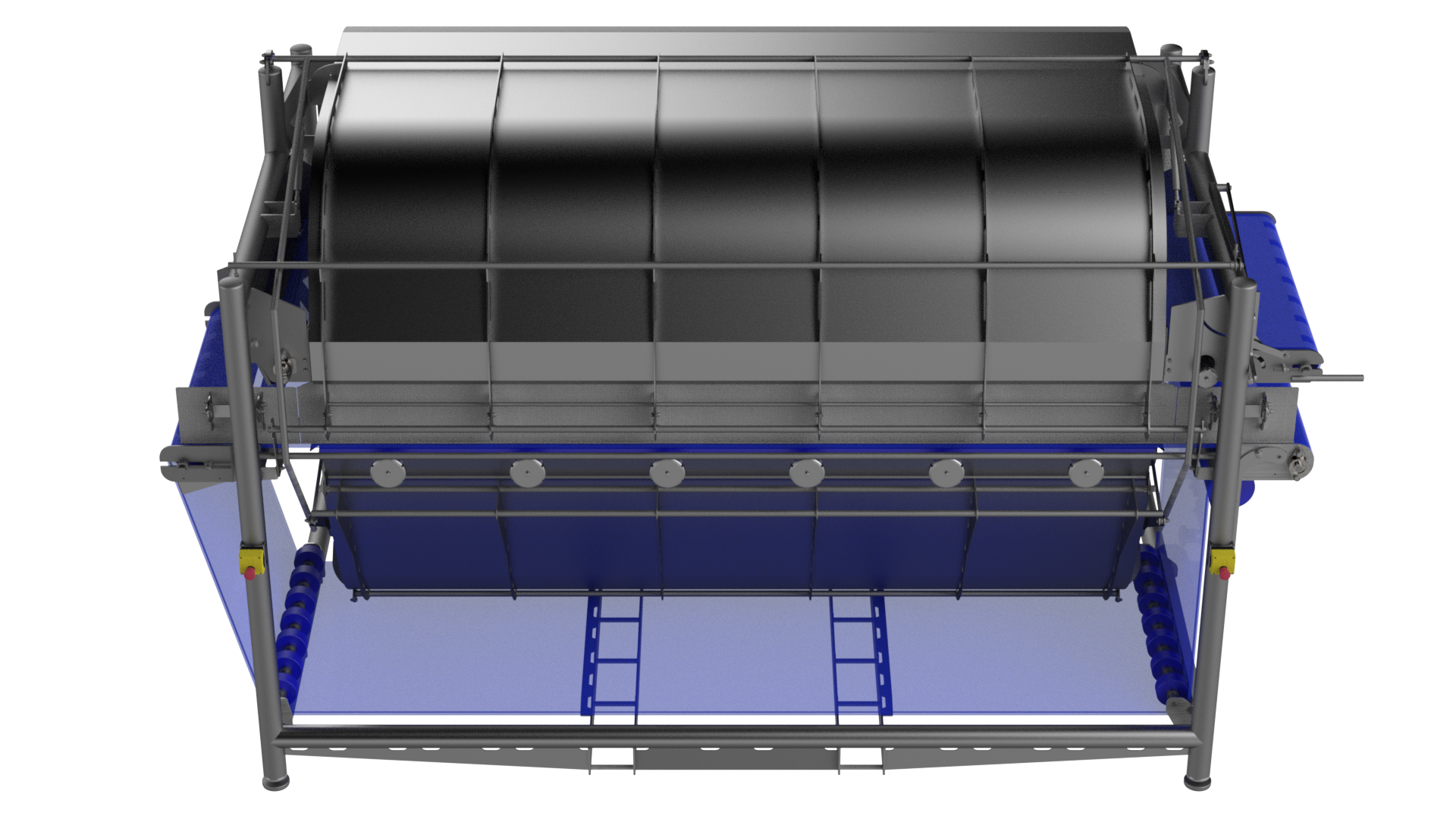

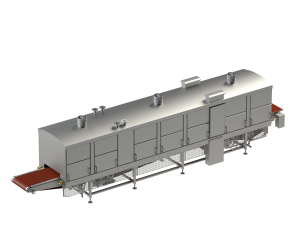

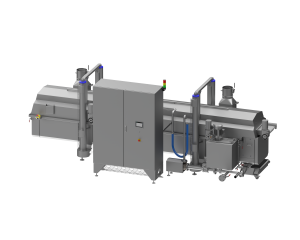

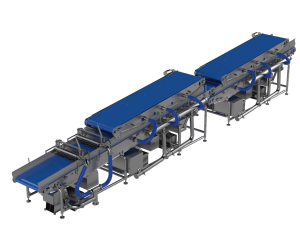

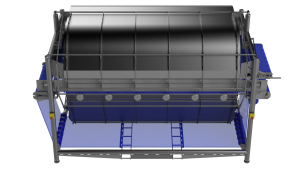

Before reaching the drying tunnel, the product goes through a preliminary de-watering step by means of a de-watering belt.The CoolDry has 2 systems for heating and cooling, with a central input for hot and cold liquids. These channels are controlled from the central control unit. These are fed from a central input of hot and cold liquids provided by the client or installed from the factory. The product will enter the CoolDry when it exits the BDS/FDS system and will be transported through the machine via the mesh conveyor belt. Warm air(between 20°C and 25°C) will be blown past the product, this conditions the product and causes any leftover moisture to evaporate. The CoolDry also provides the possibility for cooling the product. The air is cooled and de-moisturized and this cool dry air is blown past the product. This cools the product and removes the last unwanted moisture. The requested dryness can be set from 0 – 3% The CoolDry can be delivered as a complete unit with Heat and cold installed on the machine. The heat is generated by a heatpump and delivers the cold and heat. The extra energy to generate the cold energy can be used to heat up external water for cleaning or heating purpose. This reduces the energy cost

UV-C (option) Break down organic molecular bonds.

With over 35 years of experience in the Food Industry, we advise, develop and produce high-quality tailor-made stainless steel solutions. We combine specific expertise and skills and focus on high quality, service, hygiene and safety in our work.

— Hitec BV