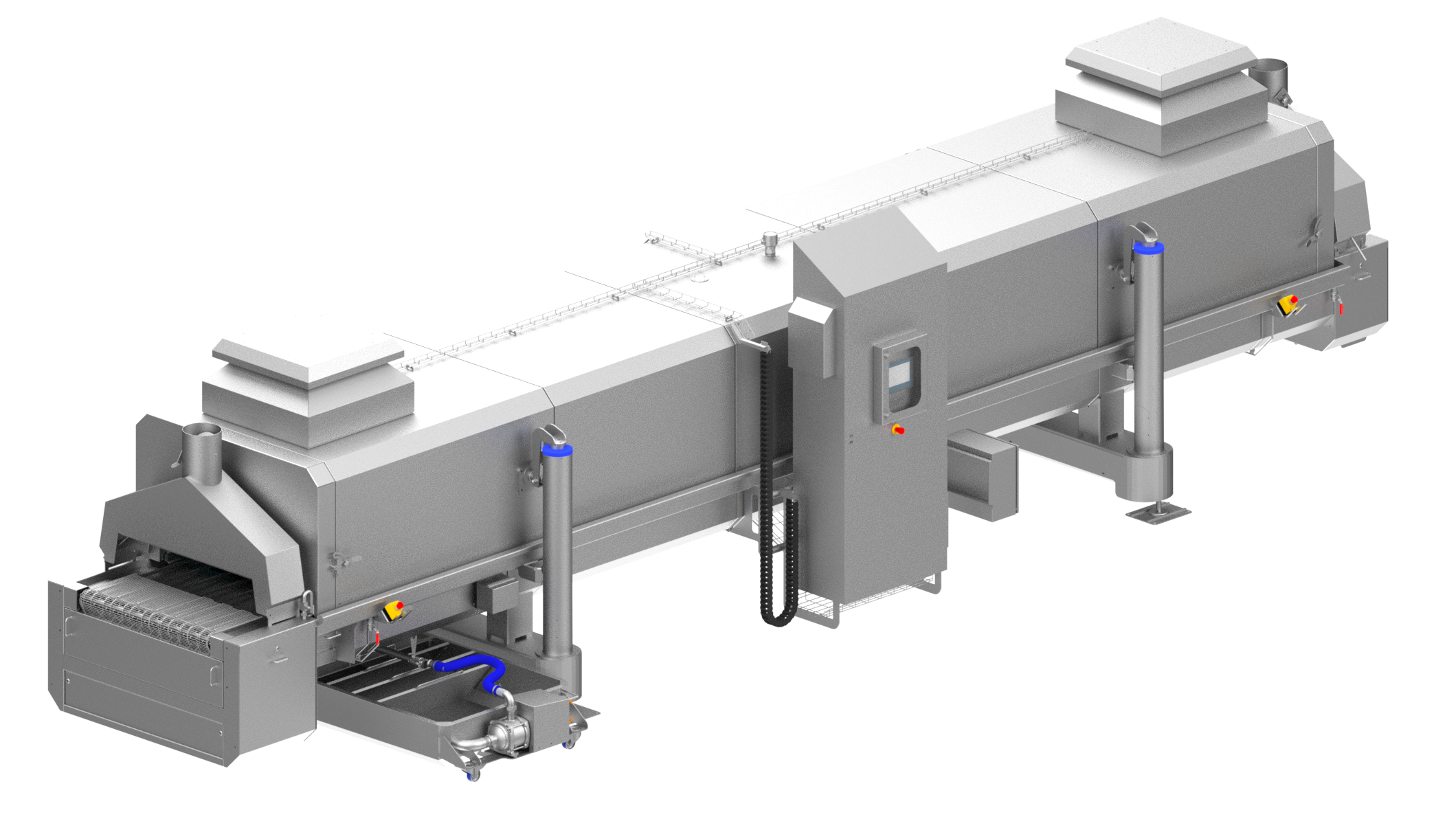

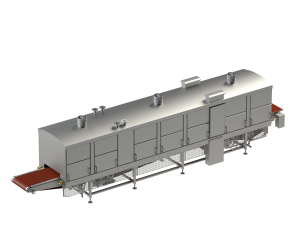

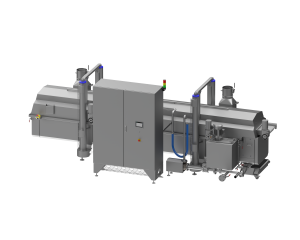

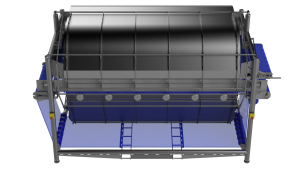

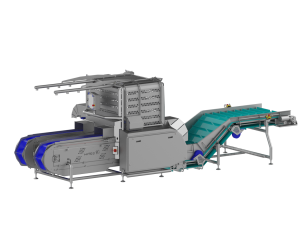

The Aircook linear oven has two heating areas available that can be tempered differently at the same time. That’ll bring you maximum efficiency

in food processing with minimized energy consumption. Top-performance heating elements ensure efficient heat transfer. Choice between

electrical and thermal oil-powered heating elements possible in up to 2 different climate zones with optional dew point control. Perfectly suitable for: hamburgers, meat

loaf, whole chickens, burgers, bacon, pretzels, vegetarian produce.

Our linear oven heats, cooks, and browns productswith circulating air and/or steam. With its dualarea system, our linear oven stands for maximum

efficiency. Two separately adjustable heating areas provide the option of cooking and browning food at the same time using different temperatures.

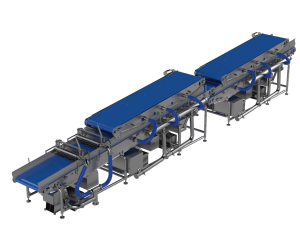

That way, the system makes perfect use of energy consumption. Different product sizes easily fit into the oven side by side, and the oven allows for

consistent and optimal cooking results and minimal losses of moisture. Results through hot circulating air and/or steam.

600 and 1,000, 1200, 1400 mm belt width

6 – 14 m effective cooking length

With over 35 years of experience in the Food Industry, we advise, develop and produce high-quality tailor-made stainless steel solutions. We combine specific expertise and skills and focus on high quality, service, hygiene and safety in our work.

— Hitec BV