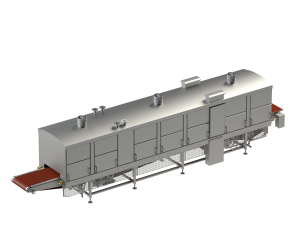

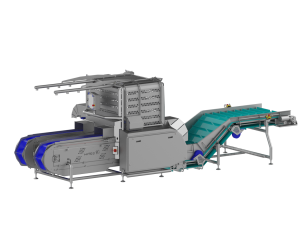

HiTec custom Fully hygienic stainless steel Cooling & Freezing Tunnels The Crucial Last Step In De Processing Line!

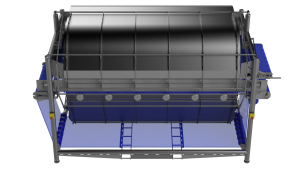

• IQF Freezing Principle

• Keeping Texture

• Extended Shelf Life better product quality!

• Controlled Process

• Product / Project Specific design

• Fully Welded Stainless Steel

• Hygienic design

• Ease Of Cleaning (CIP; time saving)

• Air Defrost or Sequential Defrost

Housing

• Fully Stainless Steel Housing

• 140 mm Thickness

• Fully Welded Inside And Outside

• Self Supporting Insulated Floor

• Compact Design

Heated Access doors with electrical tracing

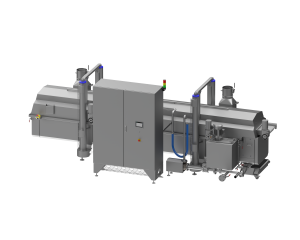

Evaporators

• Robust Design

• Reinforced Lamellae For Air Defrost

• Optimum Positioning To Reduce Ice Build Up.

• Material lamellae AlMg, Seawater Resistant.

• Supporting Plates: Stainless Steel

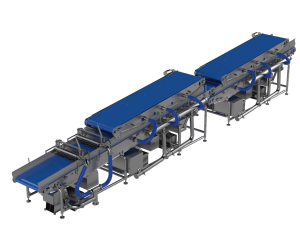

Conveyor belts

• Stainless Steel Eyelink Belt Pitch 50 mm or Volta SD Hygienic

• Spray Bars On Each Section

• Details Flexible Depending On Product

CIP nozzles

• Rotating Nozzles Above Belt

• Rotating Nozzles Behind

Evaporators

• Fixed Nozzles Above Evaporators

• Fixed Nozzles In Belt Washers

• Optional With Detergent Mixing

Station

Pre-cabling & controls as per customer specification.

With over 35 years of experience in the Food Industry, we advise, develop and produce high-quality tailor-made stainless steel solutions. We combine specific expertise and skills and focus on high quality, service, hygiene and safety in our work.

— Hitec BV